There’s a reason for the depiction of the mystical bird that rose from the ashes: Division, a commercial laundry, has clawed its way back from a fire that destroyed its plant in 2001 because of it’s laundry innovations.

When Division’s plant was leveled, “we lost 65 percent of our business,” company President Patrick R. Garcia said recently. “But can you believe it? We held on to 35 percent of our business without a plant,” as the company retained the Methodist Healthcare System and Wilford Hall Medical Center as clients.

The company survived by shipping laundry to plants as far away as Abilene, Houston and Corpus Christi. It sent employees to supervise quality control at those plants.

Division wasn’t able to rebuild for two years, but it now occupies a sprawling plant at 6649 W. U.S. 90. The company is handling almost as much business as it was before the fire, having increased poundage from July 1, 2003, when it reopened, through last year by 117.5 percent, or almost 11 percent a year, Garcia said.

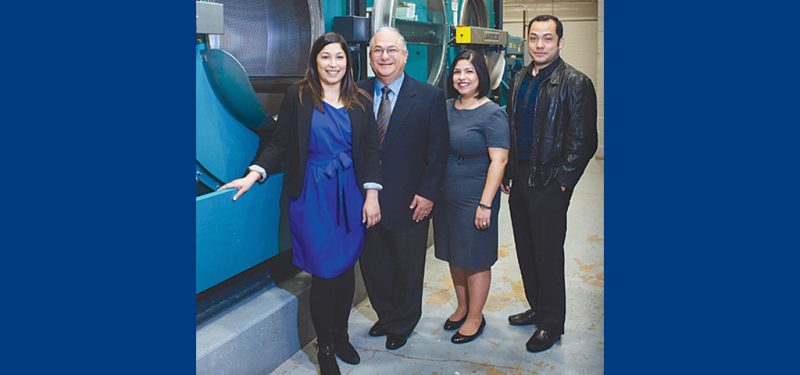

Division declined to disclose its sales, but Garcia, 60, believes that the business is the largest laundry in the city and in South Texas due to it’s laundry innovations. Each of his three children and his son-in-law have a role in the business: Patrick A. Garcia, 29, is a lawyer and vice president of finance; Patricia Garcia Luna, 30, is vice president of administration, and her husband, Adam Luna, 31, is director of purchasing; and Theresa Garcia, 26, is vice president of operations.

Division “is the only certified health care laundry” in the region, Patrick R. Garcia said. It has long-standing relationships with many hospitals. A number of hospitals, which dropped Division after the fire, later returned as customers.

“We have to show proof that we are running at temperatures that are desirable for killing pathogens,” Garcia said. “We have to show that we have checks and balances in our processes. If something fails, we have to show what we do about it.”

Once a year, an infection prevention officer from each health care system visits Division to conduct an audit that can take as long as four hours.

The Garcia family and Division “are highly respected,” said Reynaldo “Rey” Chavez, CEO of the San Antonio Manufacturers Association. Garcia is knowledgeable about water and waste issues, and “the company has been involved in a lot of issues that we care about.”

Division has deep roots in the city. Garcia’s father, Peter Garcia, founded the company in 1939 at Fort Sam Houston after shining shoes and selling newspapers downtown as a boy. He began by hand-washing uniforms of the 2nd Infantry Division and sewing patches on uniforms. He bought his first set of laundry equipment with a $100 loan from his father.

The company grew over the years under Peter Garcia.

Laundry Innovations before and after the fire helped build sales.

In 1995, Division started adding giant cylindrical devices called tunnel washers that were much more efficient than its old-style washer. The company completed the upgrade while rebuilding the plant. The new devices saved 15 million gallons of water a year.

SAWS recognized Division in 2004 for its more efficient washers because the move helped the Edwards Aquifer.

Most of Division’s water comes from an on-site Edwards Aquifer well. It uses the San Antonio Water System as a minor source and backup supply.

Patrick R. Garcia “has a long history of being personally involved with commercial water-conservation initiatives,” said Karen Guz, SAWS director of conservation. Through his membership in the SAMA, he “promoted the concept of having dedicated revenues from a small portion of commercial meters fees in order to fund commercial incentives. He has been a great supporter of water conservation in commercial settings for a very long time.”

But water isn’t the only area in which Division has been innovative. The company also added a “picker” device that separates tangled, wet sheets, saving time and sparing the backs of workers. It now is adding a computer-controlled overhead rail system that will greatly speed up the sorting of linen.

“What we’re looking at is an almost 40 percent increase in production,” Garcia said. No longer will operators need to manually load soiled linen on a conveyor belt in 110-pound loads.

“With the new system we’re installing, the plant will be able to handle as much as 42 million pounds a year,” Patrick A. Garcia said.

With the trauma of the fire long past, Patrick R. Garcia mused, “It’s exciting to have the children in here. It wasn’t planned, it just happened. The people in our industry — whether they are equipment people or hospitals, they now see continuity in the business.”

Vicki Vaughan

Reporter | San Antonio Express-News